Insights and Commentaries

CCS is essential for the continued use of brown coal in a carbon-constrained world

16th March 2016

Topic(s): Carbon capture, Engineering and project delivery, use and storage (CCUS)

Brown coal (lignite) is an abundant and low-cost source of global energy but its high water content makes it a particularly emissions intensive resource. Efficient exploitation of brown coal resources depends on emissions reduction technologies such as carbon capture and storage (CCS). To explore the potential for CCS on brown coal a pioneering international project led by Australian innovators has set up a pilot plant at the AGL Loy Yang power station in Australia's La Trobe valley. In this Insight, the Global CCS Institute's Senior Adviser for Carbon Capture, Asia–Pacific, Dr Tony Zhang discusses the PICA project and its importance for the future of brown coal.

Importance of brown coal for Victoria

Victoria has abundant brown coal (lignite) reserves, one of the largest and lowest cost energy sources in the world. The endowment of such resources enables Victoria to produce electricity at relatively low cost, albeit with relatively high greenhouse gas emissions. The installed capacity of lignite-fired power stations is approximately 6.3 GW, which makes up a major proportion of Victoria’s electricity. It will be essential for the lignite industry to utilise more efficient technologies if it is to continue to supply Victoria with low cost electricity and underpin economic growth in the Latrobe Valley.

Importance of CCS to lignite

Fossil fuels will continue to play a significant role in meeting the global energy demand. Lignite power stations generally have low thermal efficiencies, and thus have larger carbon footprints than more efficient black coal power stations. In a carbon-constrained world, continued use of such fossil fuel resources requires the adoption of carbon capture and storage (CCS) to reduce its carbon footprint. CCS is capable of reducing the emissions of lignite-based power stations by up to 90%.

Current status of lignite CCS

CCS has been successfully implemented for a lignite-based power station in Canada. In October 2014, the Boundary Dam Project in Saskatchewan was commissioned to capture carbon dioxide (CO2) from a lignite-based power station. The plant produces high purity CO2 for permanent storage and enhanced oil recovery (EOR) at nearby oilfields. The Kemper County Project in the United States is another lignite-based power station integrated with CCS. This project uses integrated gasification combined cycle (IGCC) and is scheduled to start in 2016. CCS for industrial processes is a relatively mature technology, having been applied in natural gas processing and fertiliser production for many years.

Challenges

The installation of CCS at a coal-fired power station requires significant capital investments and the capture process incurs significant energy penalty which increases the cost for electricity generation. The widespread commercial deployment of CCS requires the reduction of carbon capture cost, which usually comprises the majority (70-90%) of the whole chain CCS cost. Industry, research institutions and other organisations have been working on ways to reduce cost for carbon capture. In addition to cost, there are other technical issues to be addressed for the deployment of CCS. For example, the presence of impurities in flue gas may have a substantial impact on the design and operation of a carbon capture plant.

CCS R&D needed in Victoria

The flue gases from Victorian lignite power stations have some unique features which call for local carbon capture demonstration activities designed to accumulate knowledge and learning in this specific context. Such pilot work would pave the way for the future deployment of CCS in Latrobe Valley, by acquiring more local expertise and accumulating more site-specific know-how for adaptation and operational issues.

In the following, a carbon capture pilot project is included as an excellent example case study to highlight the importance for continued CCS R&D for lignite.

Case study – the PICA project

AGL Energy Limited, IHI Corporation, CSIRO and Brown Coal Innovation Australia have been working together to establish a carbon capture pilot plant in the PICA project since 2014. The project aims to reduce the capture cost by 40% by investigating solvents, equipment and process design. Another objective of the project is to investigate the effects of impurities, such as sulphur oxides (SOx). Australian coals (both black and brown) are very clean by world standards, so local power stations are not equipped with desulfurisation units. Still, the flue gases contain concentrations of SOx that are normally not tolerated by the CO2 capture process.

The capture pilot plant is designed and manufactured by IHI Corporation. It is solvent-based and has a CO2 capture capacity of 0.5 tonnes per day (tpd) which is equivalent to electrical output of approximately 0.025 megawatts (MW). Process improvements will be investigated in three aspects:

- Solvents: testing two advanced amine solvents

- Process design: using two advanced process configurations

- Equipment: adding an advanced gas/liquid contactor

To be more specific, the project will study the following factors:

- Energy penalty for carbon capture

- CO2 capture rate

- Breakdown products and composition

- Emissions

- Operating window optimisation

- Corrosion

- Material

The pilot plant has been delivered to AGL Loy Yang power station and construction and interfacing with the power station is now complete; the launch is expected in early 2016. Following commissioning, a two-year operation will be conducted to investigate the aforementioned parameters.

International collaboration

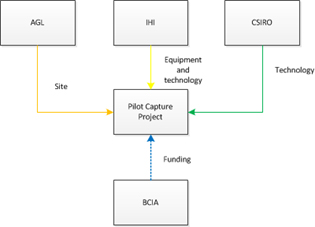

A key and unique feature for this project is the breadth/dimension of international collaboration. This project involves multiple partners from different industries and different countries. An organisational chart of the project is presented below.

Figure 1. PICA Project Partnership Structure Chart

The role of each party in the project is listed as follows:

AGL Loy Yang:

AGL owns the host facility – AGL Loy Yang power station – which provides flue gas, electricity, water and waste management for the pilot capture plant.

CSIRO:

The Commonwealth Scientific and Industrial Research Organisation (CSIRO) will support the design work, commission, and operate the IHI plant at AGL Loy Yang power station, and evaluate its own proprietary capture system.

IHI Corporation:

Design, construct, transport, and operate the 0.5 tpd pilot plant based on its own proprietary technology in Japan.

BCIA:

Brown Coal Innovation Australia Limited (BCIA) has provided AUD$650,000 funding to support the AUD$5.3M research project.

Among the project partners, CSIRO brings great industrial R&D strengths in carbon capture. This project provides an opportunity for CSIRO to intensify its collaboration with industry. It is also a recognition of the leading carbon capture R&D capabilities in Australia. IHI Corporation aims to utilise the local expertise built up around lignite and carbon capture. Its business strategy includes the development of carbon capture technology. AGL, as a power generator, will develop learning in project management, technology development and CCS deployment for lignite power stations in the Latrobe Valley, Victoria. As a member-based company, BCIA’s aim is to support innovations that reduce the environmental impact – and deliver social and economic benefits – from sustainable use of lignite.

This collaboration between a power generator, a technology supplier, and an R&D organisation is not only a cross-border one between Australia and Japan, but also one along the innovation chain. It was observed that there is an increasing appetite for this type of collaboration for CCS development. Consider for example, the U.S. Department of Energy-funded CCS R&D activities outside the U.S.

Substantial carbon capture technology research and development efforts are being made around the world. Australia has been recognised as having a prominent and pioneering role in this space. Many local innovations have been made in carbon capture. It is important for various stakeholders to work together on issues of common interest, and to have more effective communication regarding technology progress. Global collaboration and knowledge sharing will reduce unnecessary repetitive R&D activities, provide synergies in common development, and accelerate the development of carbon capture technology towards the reduction of carbon capture cost.

This project is a great example of international collaboration and technology innovation. Victoria hosts substantial lignite reserves, and more importantly, according to IHI Corporation it is "a focal point for leading-edge research in this area". Therefore it is critical to build on this local expertise to continue the cause of emission reduction technology development for brown coal.